Now available in MX packages, the all-in-one PathPilot Operator Console allows users to operate their M or MX machines with built-in hardware knobs for feed and speed overrides and a durable hand-held jog pendant for precise manual positioning of the machine. In addition, Tormach has launched an updated PathPilot Operator Console upgrade. "When combined with Tormach's PathPilot CNC controller, which provides users with numerous premium features as standard, these machines provide the highest performance and most cost-effective machining solutions on the market today," said a company spokesperson. The servos provide much faster performance with maximum speeds up to 10,000 RPM and feedrates as much as 2.5-3x faster than the M series machines.

The MX series of machines feature an added encoder to the spindle for rigid tapping, a BT-30 spindle and servos for the X, Y and Z axes. The new MX series are servo-driven versions of the company's mills, the 1100M and 770M, which were introduced in 2018.

has introduced its latest CNC mills, the 1100MX and 770MX. See Shipping Tab for full details.Tormach Inc. Freight charges and sales tax will be calcualted by Tormach and will be added to your order prior to shipping. **NOTE - ADDITIONAL CHARGES WILL APPLY** - This machine ships directly from a Tormach warehouse. This starter package includes the Tormach 440 PCNC Mill, PathPilot® controller, chip pan, standard LCD monitor, waterproof mini keyboard, jog shuttle controller, 4" CNC Vise, manual operator set (inch), cutting stool starter set, cable kit, and 1 gallon of machine way oil. The PCNC 440 is rated to cut aluminum, steel, titanium, as well as plastics, composites, wood, and PCB boards. The way surfaces are low friction PTFE-filled Acetyl bonded sliding surfaces similar to Rulon® and Turcite®. It has a cast iron frame and table with hand-scraped hydrodynamic ways and tapered adjustment gibs. It also incorporates rolled C7 ball screws with anti-backlash double ball nuts.

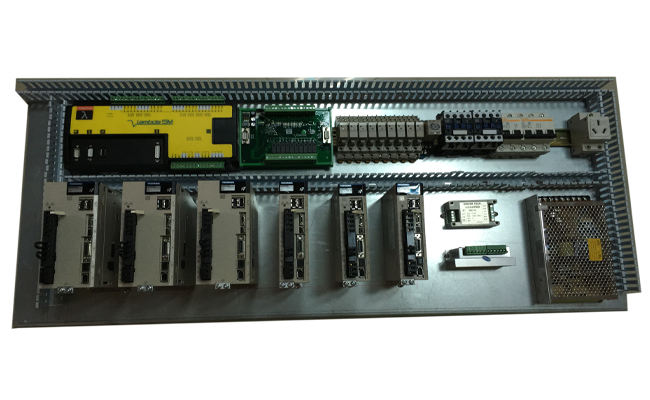

The PCNC 440 offers high-performance bipolar stepper motors with Leadshine micro stepping drivers. The typical footprint of the PCNC 440 is 42″ × 36″ (1067 mm x 914 mm) which allows for bench top use or mounting on the optional stand. A machine that fits all-around capability in a compact and affordable package, the PCNC 440 is perfect for anybody that wants to do real cutting but doesn’t have a lot of space.

0 kommentar(er)

0 kommentar(er)